Transitioning to clean energy technologies is a monumental global effort aimed at reducing carbon emissions, mitigating climate change, and moving away from burning fossil fuels like coal, oil, and natural gas. Many countries have pledged to pursue net zero emissions targets under international frameworks such as the Paris Agreement, with an eye toward keeping warming near pre-industrial levels to avoid the worst impacts of climate change. Meeting these goals involves a dramatic scaling-up of renewable energy sources—like solar and wind power—so we can generate electricity without harmful greenhouse gases. Yet, to achieve net zero and help communities reap the benefits of an equitable clean energy transition, we must overcome critical supply chain bottlenecks.

Below, we’ll explore the top five challenges in the clean energy supply chain—everything from raw material constraints to logistics and labor shortages—and we’ll show you how MSS International can help. We’ll also weave in practical tips, real-world data, and insights into how countries, businesses, and communities can collaborate to create the enabling environment needed for a fair transition. By the end, you’ll see how these challenges intertwine with broader topics like energy security, affordable energy, and the global transition to renewable energy.

Weak Link #1: Raw Material Constraints and Geopolitical Concentration Hinder the Energy Transition

If you look at most modern clean energy solutions—from solar power to electric vehicles—you’ll find that they rely on critical raw materials. Lithium, cobalt, copper, and rare earth elements are just a few examples of the minerals essential for building batteries, wind turbines, and other renewable sources of power. The challenge? Many of these materials come from a handful of countries, making the global transition to renewables vulnerable to supply disruptions.

For instance, the International Energy Agency (IEA) estimates that China alone accounts for more than 80% of certain stages of solar panel manufacturing, including the production of polysilicon and solar wafers. This concentration means a single geopolitical event, trade dispute, or natural disaster could disrupt the world’s supply of solar panels—slowing our ability to generate electricity from cleaner sources and exacerbating greenhouse gas emissions. Meanwhile, the demand for lithium (essential in electric cars and stationary energy storage) is set to rise at least fivefold by 2030 as more people embrace EVs in the push to reduce carbon emissions and achieve net zero.

Real Data and Statistics

- Lithium Demand: Forecasts suggest a 400% to 500% increase in global lithium demand by 2030, driven largely by the expansion of electric vehicles.

- China’s Manufacturing Dominance: Approximately 80% of all solar panels globally are produced in China, amplifying geopolitical risks.

- Supply Chain Delays: The US Department of Energy warns that disruptions in one major supplier region could lead to project delays of 6 to 12 months, impacting everything from renewable energy development to broader climate action efforts.

Solutions

- Diversification: Encouraging more countries to mine and process critical minerals, and providing incentives (like the US Inflation Reduction Act) for domestic manufacturing. This strategy ensures that we’re not overly reliant on a single supplier—particularly in an era of evolving trade policies.

- Recycling & Circular Economy: Establishing robust recycling programs for old EV batteries and solar panels. By capturing precious metals from end-of-life products, we reduce waste and lessen our dependence on raw material extraction.

- Technology Innovation: Developing battery chemistries that rely on more abundant minerals such as sodium, or reducing the reliance on expensive and rare components. Some research efforts even focus on battery recycling that can recover up to 95% of critical materials.

Why It’s Important for the Energy Future

By addressing raw material bottlenecks head-on, you help create a more stable, resilient, and sustainable energy future. Without enough lithium, copper, or rare earths, it becomes far more challenging to scale up solar power, electric vehicles, or other renewable energy sources that are crucial for achieving net zero emissions and stabilizing our climate. Diversification, recycling, and technological innovations all work together to give many countries an opportunity to reduce their dependence on burning fossil fuels and transition to cleaner alternatives.

Weak Link #2: Insufficient Manufacturing Capacity for Clean Energy Solutions

Think about how quickly the world needs to deploy renewable energy sources—like solar and wind—to hit net zero targets. According to the Energy Transitions Commission, annual solar and wind capacity additions must ramp up by at least three to four times by 2030 compared to current rates. However, manufacturing capacity for key components doesn’t always keep pace with this demand.

Solar panel manufacturing has seen rapid expansion, hitting 1000 GW of potential module assembly capacity by 2024. Yet, wind turbine production—especially for offshore wind farms—lags behind. Some analyses show that by 2030 we’ll need significantly more wind power equipment than manufacturers currently have the capacity to build. Similarly, electrolyzer manufacturing for green hydrogen, a big part of future energy solutions, also faces scaling issues. If we can’t produce enough equipment, we risk missing crucial milestones on climate action and increasing reliance on fossil fuels.

Data Points

- Wind Manufacturing Growth: Wind turbine component production has grown by only around 2% annually in some segments, far below the pace needed to meet 2030 projections.

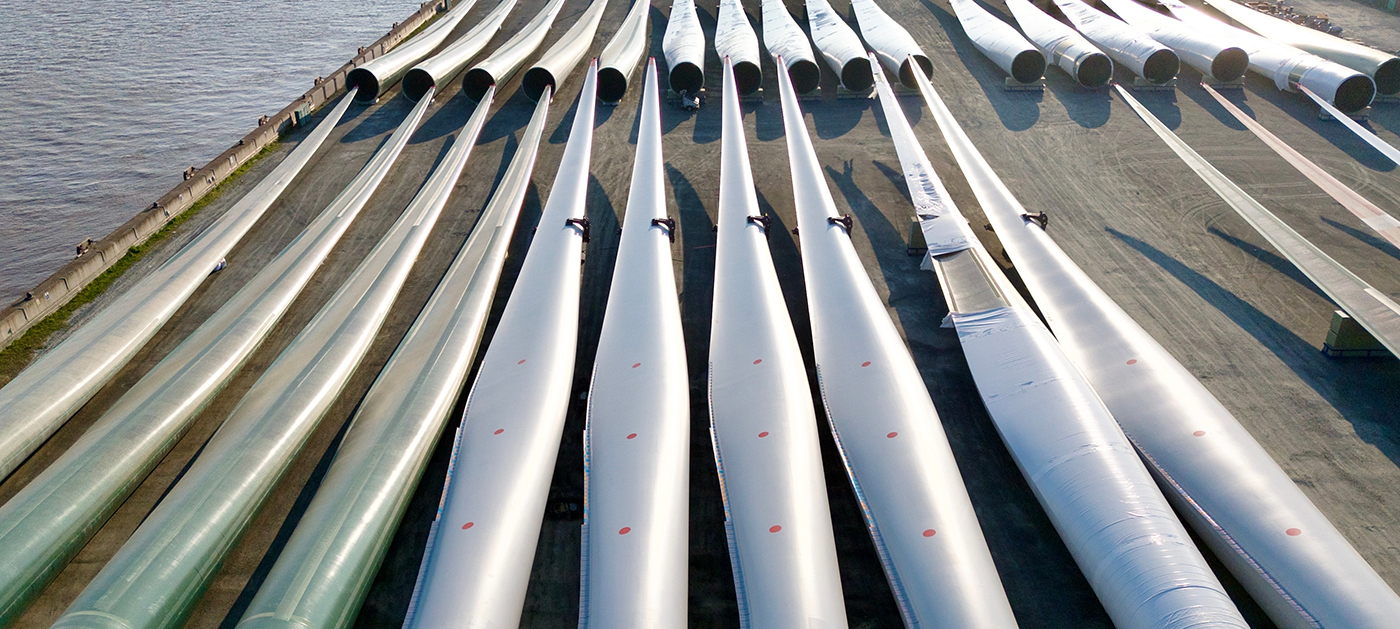

- Long Lead Times: Large offshore wind components, such as blades that can exceed 80 meters, involve highly specialized factories with lead times of 12 to 24 months. This slow turnaround can hold back big projects that could otherwise generate vast amounts of clean electricity.

- Hydrogen Electrolyzers: Government and private sector ambitions project at least a 20% annual increase in electrolyzer capacity. However, experts estimate the world will still fall 40% short of what’s needed to align with net zero.

Potential Solutions

- Localisation & Onshoring: Many countries introduce incentives—like the EU’s Net-Zero Industry Act—to encourage local manufacturing of solar and wind components. Local manufacturing not only creates jobs but also boosts energy security and shortens supply chains.

- Public-Private Partnerships: By coordinating efforts across government agencies and private sector players, we can build robust manufacturing ecosystems. Grants, low-interest loans, and streamlined permitting can speed up factory construction.

- Standardisation & Innovation: Standardizing component designs (e.g., modular turbine sections) can reduce manufacturing complexities and accelerate production. Meanwhile, advanced manufacturing techniques—like 3D printing—cut lead times and material waste.

Connecting to Climate Goals

Insufficient manufacturing capacity doesn’t just drive up project costs or cause schedule slippage; it also hinders progress toward critical net zero deadlines. Without enough solar panels or wind turbines, you rely more heavily on burning fossil fuels to meet energy demand. This, in turn, drives up emissions and undermines the benefits of an equitable clean energy transition. Overcoming manufacturing bottlenecks is crucial for staying on track with global climate commitments and safeguarding public health, well being, and future prosperity.

Weak Link #3: Warehousing and Inventory Management Issues Slow the Clean Energy Transition

Imagine you’re developing a massive solar farm in a remote region. You have thousands of panels, miles of cables, inverters, and support structures arriving in waves. Storing and organizing these shipments requires specialized warehouses, real-time inventory tracking, and strict quality control. The same is true for wind power projects: you can’t just tuck 80-meter blades into a standard warehouse.

Logistical complexity spikes when components arrive at different times and from different renewables suppliers around the world. If you don’t have an efficient warehousing solution, you risk delays, damage, or inventory mix-ups—any of which can set your project back by months. And in the race to mitigate climate change, every lost month is costly.

The Data & Stats

- Oversized Infrastructure: Wind turbine blades can exceed 80 meters, while tower segments can weigh hundreds of tons, making conventional storage nearly impossible.

- Seasonal Peaks: Renewable energy construction often surges at specific times of the year (e.g., before policy incentives expire). If warehouses aren’t prepared for these spikes, congestion can lead to project standstills.

- Costly Idle Time: Some studies suggest that delayed or idle inventory can account for up to 10% of total project costs in large-scale renewable energy development.

Solutions for Better Management

- Flexible Warehousing: Partner with logistics providers offering “dynamic” or “on-demand” warehousing, where space can be scaled up or down as needed. This approach minimizes overhead in slow periods but accommodates surges when shipments arrive.

- Advanced Tracking Systems: Embracing IoT (Internet of Things) and RFID tags for real-time visibility of components can significantly reduce waste and misallocation.

- Climate-Controlled Storage: Batteries, inverters, and other sensitive components might need regulated temperatures and humidity to preserve their lifespan.

Real-World Implications

If warehousing and inventory management break down, even the best manufacturing pipeline can be derailed. That’s why these logistical issues must be front-and-centre if we want to meet net zero and climate action targets. Projects that stall due to storage confusion risk losing funding, stalling job creation, and diminishing public trust in the clean energy future. Effective, secure, and agile storage solutions are essential for ensuring an unbroken chain from factory to installation site.

Weak Link #4: Distribution and Logistics Complexities Slow Building the Clean Energy Future

Distributing renewable energy equipment can be a nightmare if you’re not prepared. Oversized wind turbine blades, high-voltage transformers, and delicate solar panels require specialized shipping, which is in short supply. Moreover, global supply chains remain vulnerable to disruptions like port congestion, container shortages, or unforeseen geopolitical events.

Take the example of shipping an offshore wind nacelle (the big housing that sits atop the turbine tower). These nacelles can weigh hundreds of tons, requiring unique vessels, specialized cranes, and multiple permits to move across countries and oceans. Any logistical hiccup along the way can cost millions and delay the entire project timeline, threatening the progress of your energy solutions and the broader drive to replace fossil fuels with cleaner sources.

Hard Data

- Global Freight Bottlenecks: During the COVID-19 pandemic, freight rates soared by over 300% on some routes, and shipping delays became the norm. These disruptions didn’t just affect consumer goods; they also impacted solar panel and turbine component deliveries.

- Oversized Cargo Limits: Many roads and bridges, particularly in emerging economies, aren’t designed for transporting massive wind blades. This severely limits feasible project sites or demands expensive infrastructure upgrades.

- Hazardous Cargo: Electric vehicle batteries or hydrogen fuel systems are classified as hazardous, requiring strict adherence to safety regulations. Additional paperwork, specialized containers, and extra caution add complexity and expense.

Proposed Solutions

- Integrated Logistics Services: Working with a single logistics provider that manages end-to-end shipping—from factory gate to project site—can reduce handoff issues. DHL and Schneider have renewable energy-focused divisions offering precisely this kind of service.

- Route Planning & Tech: Digital tools that factor in road weight limits, real-time congestion, and weather forecasts help map out safe, efficient paths for oversized equipment.

- Multimodal Transportation: Combining sea, rail, and road transport can optimize costs and reliability. Rail might be better in some regions, but shipping by sea might be essential in others.

- Local Assembly: In some cases, partial assembly near the project site can reduce the need to transport massive, fully built components over land.

Why It Matters for a Just Transition

Poor logistics can freeze progress in building solar farms, wind farms, or installing battery energy storage systems. If that happens, communities may be forced to keep burning fossil fuels to meet electricity demand. By smoothing logistics and ensuring timely deliveries, we can accelerate the arrival of a fair transition to renewable energy—one that benefits local well being, stabilizes electricity networks, and reduces greenhouse gases in the fight against climate change.

Weak Link #5: Workforce and Quality Control Risks Across Global Energy Technologies

With renewable energy surging, the demand for skilled workers—engineers, factory technicians, logistics experts—has never been greater. The clean energy sector added hundreds of thousands of jobs worldwide in recent years, but as many countries sprint toward net zero, the competition for talent intensifies.

At the same time, rapid investments in the expansion of manufacturing lines can compromise quality control if not handled carefully. Ramping up production quickly might leave insufficient time for rigorous testing and compliance checks. If defective solar panels, turbines, or batteries make it to the field, repairs and replacements can cost millions, not to mention eroding public confidence in the private sector’s ability to deliver clean energy solutions effectively.

Statistics

- Labor Demand: The International Renewable Energy Agency (IRENA) projects up to 42 million jobs in renewables by 2050, a massive increase from current levels.

- Quality Control Costs: Studies suggest that quality-related issues can add up to 5-10% to a project’s overall cost if products arrive defective or fail prematurely.

- Training Gaps: Many training programs are still not fully aligned with the complex realities of installing and maintaining solar and wind technologies, leaving a shortfall of skilled technicians.

Possible Solutions

- Upskilling & Reskilling: Governments and companies alike can sponsor targeted training initiatives, particularly in communities transitioning from coal and other fossil fuels. This approach fosters a more equitable clean energy transition by ensuring no worker is left behind.

- Automation & AI: Automated assembly lines, combined with AI-driven quality inspection, help maintain consistency even as production scales.

- Certification & Standards: Clear industry standards and certifications ensure that new factories meet baseline quality requirements, no matter how quickly they ramp up output.

Achieving Net Zero with a Skilled Workforce

A robust workforce is the backbone of any successful energy transition. Skilled labor ensures that solar panels are installed correctly, turbines function at peak capacity, and new technologies like hydrogen electrolysis are deployed safely. This synergy between human expertise and innovative processes helps us generate electricity from clean energy sources more reliably, keeps project costs down, and secures the buy-in of local communities eager for sustainable progress.

MSS International’s Approach to Overcoming Supply Chain Challenges

Now that we’ve explored the major bottlenecks in renewable energy production, you might be wondering: Who’s tackling these issues on a practical level? We are. MSS International is a company dedicated to manufacturing precision-engineered components and assemblies essential for the global energy transition.

Global Production and Local Delivery

One of the best ways to reduce shipping costs, boost energy security, and accelerate project timelines is sourcing components closer to their final destination. MSS International operates strategically located manufacturing and distributionand/or sales and service centres in India, Poland, France, Germany, the UK, and the USA, ensuring reliable and timely delivery of critical components.

- Shorter Supply Chains: MSS’s global footprint significantly reduces lead times, minimizing potential disruptions.

- Tailored Solutions: MSS supplies specialized components and custom assemblies designed specifically for local project requirements, ensuring reliability and optimal performance.

Advanced, Customized Manufacturing

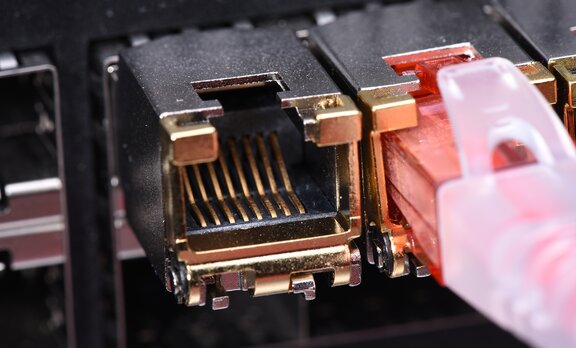

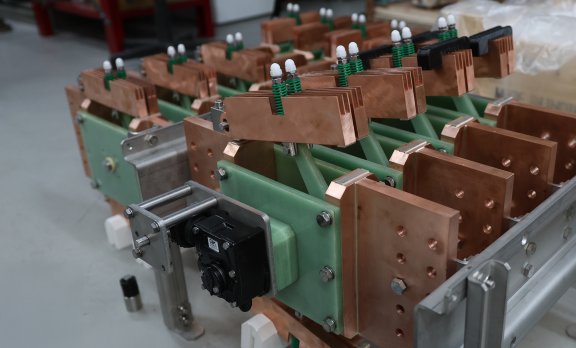

MSS International excels in precision component manufacturing, utilizing advanced CNC, VMC machinery, copper stamping, punching, bending, laminations, and hot forging technologies. Their commitment to high-quality materials and rigorous quality inspection processes ensures superior performance in demanding electrical environments.

- Quality Assurance: MSS delivers meticulously tested electrical contact assemblies and components, significantly reducing the risk of downtime due to equipment failure.

- Material Excellence: Leveraging premium copper and precision-engineered metals, MSS aligns with global standards to ensure reliable and sustainable component solutions.

Flexible Warehousing and Inventory Management

Your renewable energy project may face sudden shifts in schedule, scale, or permitting timelines. MSS International provides flexible warehousing and inventory management solutions to help you adapt efficiently.

- Dynamic Storage Solutions: MSS maintains adaptable warehouse capacities to manage inventory fluctuations seamlessly.

- Real-Time Inventory Visibility: Advanced tracking systems ensure you always have accurate, up-to-date information about your component availability, enhancing project predictability and reducing waste.

Integrated Supply Chain Solutions

Rather than managing multiple suppliers across manufacturing, sourcing, and logistics, MSS International simplifies your supply chain by providing comprehensive solutions. From component design and manufacturing to global sourcing and reliable distribution, MSS ensures streamlined, efficient project execution.

- Single-Source Efficiency: MSS coordinates all aspects of component manufacturing and logistics, simplifying procurement processes.

- Reduced Risk: By centralizing accountability, MSS mitigates logistical risks and ensures dependable, timely delivery of critical components and assemblies.

With MSS International, you gain a reliable partner dedicated to ensuring your renewable energy projects proceed smoothly, efficiently, and effectively, bringing the clean energy future closer within your reach.

Building a Cleaner, Fairer Future Together

Ultimately, every obstacle on the path to a clean energy future—from raw material bottlenecks to logistical complexity—can be overcome with the right commitments, partnerships, and technology. While countries and private sector players continue to innovate and invest, MSS International stands ready to provide the expert support and integrated solutions needed to keep renewable energy projects on track. By working together, we can transition away from fossil fuels, improve energy security, and pursue net zero emissions for the well being of communities everywhere. It’s a future shaped by determination, collaboration, and a shared promise of sustainable progress.

Back to resources